Services

MILLWRIGHT SERVICES

At Parr Industrial we offer 24/7 on-site repairs for many industries:

- Water and waste water plants

- Refineries

- Gas compression and oil pumping stations

- Air terminals

- Fertilizer plants

- Rail Facilities

- Manufacturing Plants

- Hospitals

- Education Facilities

Parr Industrial can do in house or on-site equipment rebuilds and laser alignments. We can relocate your equipment and make sure the efficiency in maximized. Rigging, hoisting, and setting/levelling new equipment is carried out by the experienced and dedicated trades people on our team. Having your equipment set up properly will save you money and countless headaches down the line. Parr Industrial does it right!

PUMPS

We service all brands and types of pumps. From industrial pumps to HVAC pumps, we have the experienced tradespeople to take care of your repairs and installs.

If we don’t have it in stock we can order it! Our list includes, but is not limited to:

- Gear Pumps

- Progressive Cavity Pumps

- Blowers

- Centrifugal Pumps

- Compressors

- Vacuum Systems

- Diaphragm Pumps

- Plunger/Piston Pumps

- Vertical Turbines

- Vane Pumps

LASER ALIGNMENT AND THERMAL GROWTH

When machines run in alignment, they operate at their best possible efficiency. Running a machine with misaligned shafts affects it efficiency and reliability. It has been estimated that worldwide, up to 50% of all costs related to rotating machinery breakdowns are due to shaft misalignment problems. Reliability centred maintenance will greatly improve the run time and operating cost of your rotating equipment. Coupling, sprocket and pulley alignment along with thermal growth monitoring are very important to the smooth running cost effective operation of pumps and gear boxes. Click here.

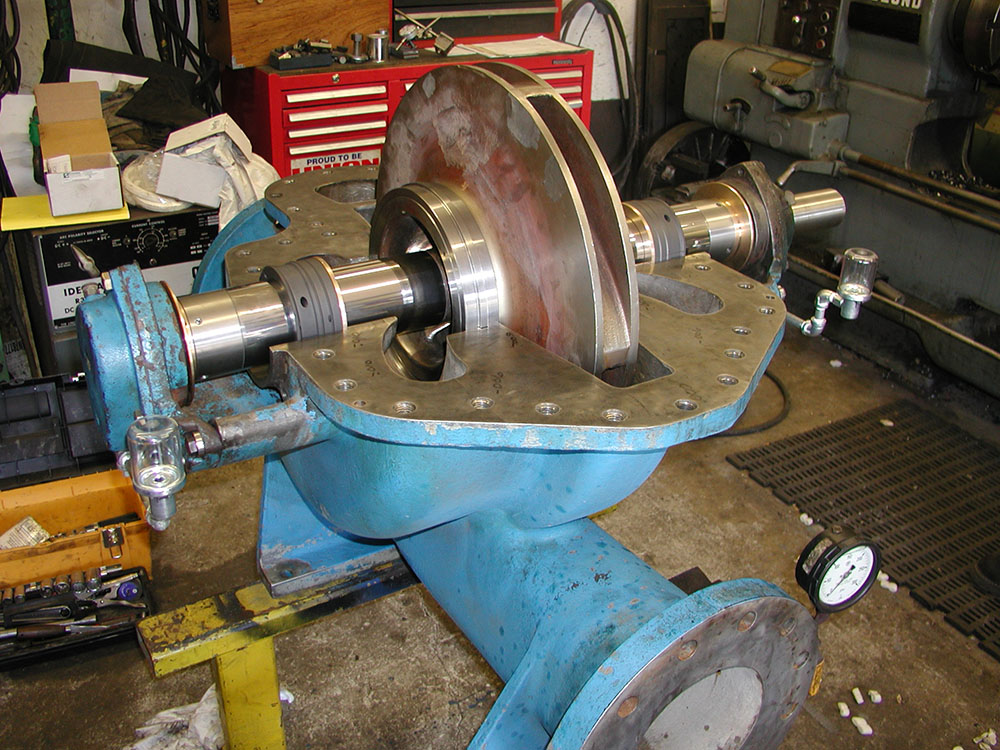

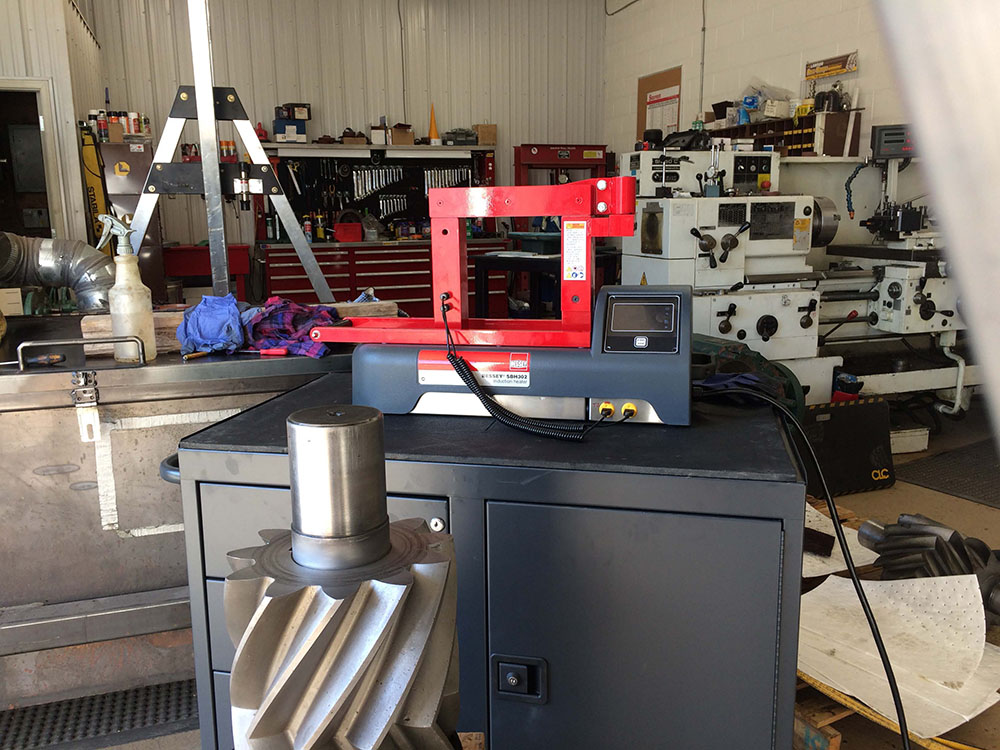

EQUIPMENT REBUILDS

Our qualified trades people are dedicated and caring people who take great pride in bringing your equipment back to its original operating condition. Parr Industrial provides on-site repairs and in house rebuilds of all brands of pumps, gear boxes, fans, air compressors, conveyors, and large HVAC equipment.

BENEFITS OF VIBRATION MONITORING:

- Identify potential machine problems

- Reduce downtime and secondary damage

- Increase machine productivity

- Improve plant safety

- Controlled maintenance planning

- Save on maintenance costs

- Reduce spare parts inventory

- Increase machine life

PROBLEMS DETECTED BY VIBRATION MONITORING:

- Bent Shafts

- Belt Drive Concerns

- Worn or Damaged Bearings

- Worn or Damaged Gears

- Lubrication Issues

- Misalignment

- Out of Balance

- Loose Fittings or Foundation

- Resonant Frequencies

- Soft Foot Problems

VIBRATION MONITORING

WOULD YOU LIKE TO HAVE AN EARLY WARNING WHEN IT COMES TO PROBLEMS DEVELOPING WITH YOUR MACHINES?

All rotating equipment in your facility vibrates to some degree. As the bearings and components reach the end of their life cycle, they will cause a more noticeable vibration. Problems other than mechanical can cause vibration as well. Vibration monitoring allows us to collect data on rotating machinery and assists us in diagnosing equipment conditions. The key is turning data into actionable information, determining if the machinery has any problems, and if so, what to do next. . .

VIBRATION MONITORING IS IDEAL FOR:

- Motors

- Pumps

- Fans

- Gear Boxes

- Conveyors

- HVAC Equipment

DON’T WAIT TO PERFORM THE NECESSARY MAINTENANCE ON YOUR MACHINERY. . .

Call Parr Industrial today to discuss your maintenance requirements

Moose Jaw: 306-693-4441

Regina: 306-779-4441

CONVEYOR SERVICE

When it comes to conveyors, we can do the construction, installation, testing, troubleshooting, repair and maintenance on all types. Glide Path conveyors, like the ones pictured here, to fertilizer conveyors, we have the trades people to install and maintain them.

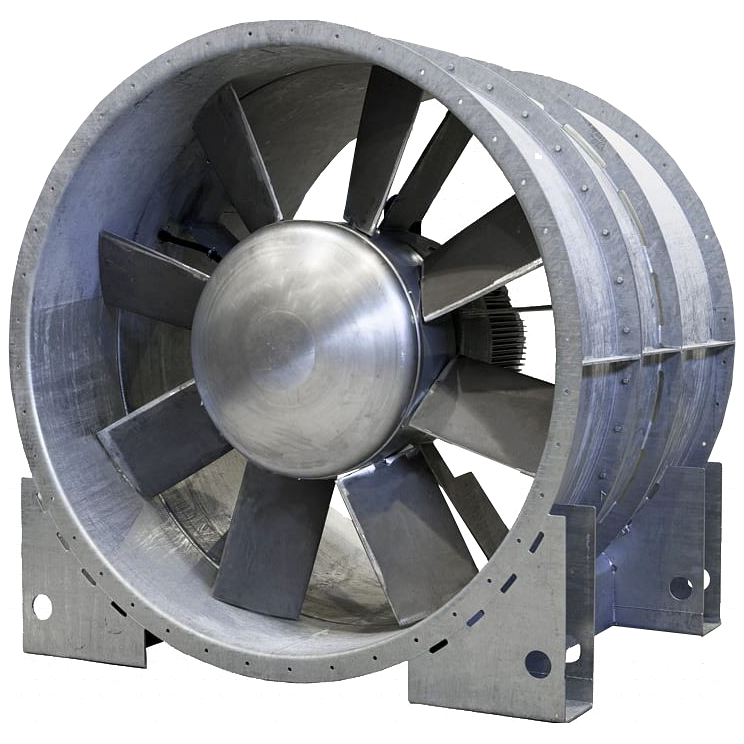

FAN SERVICE

Fan Services:

- Repair

- Installation

- Troubleshooting

- Equipment Evaluation